7.6.2019 Affalterbach. Four wins: With up to 310 kW (421 HP) to power the completely newly developed Mercedes-AMG 2.0-Liter engine M 139 is the most powerful series-produced four-cylinder turbo engine in the world. Mercedes-AMG surpassing the previous M 133, the selected so far, the top to 30 kW(40 HP).

Therefore, the maximum torque increased from 475 to 500 Newton-meters. With a power output per liter of up to 155 kW (211 HP) puts the new Mercedes-AMG high-performance turbo engine in front of many renowned super sports car engines. The new, highly efficient power is produced plant in Affalterbach according to the principle of “One Man, One Engine” on an innovative production line.

The four-cylinder in the compact models from Mercedes-AMG in two power levels for highly agile propulsion: 310 kW (421 HP) as a so-called S-model and with 285 kW (387 HP) in the base variant. This offer logic has proven itself in the AMG Performance models with a V8 engine already and still fulfils the wishes of the individual customer.

In addition to the pure performance, the new engine excels by its spontaneous response behaviour. For this purpose, the torque has been tuned over the course of consuming (“Torque shaping”): The maximum value of 500 Newton metres (480 Newton meters in the base variant) is in the range of 5.000-5.250/min (4.750-5.000/min in the base variant) are available. With this interpretation, the AMG engineers achieved a naturally aspirated engine-like power development, the emotional experience of driving effect significantly increases. The engine developers were able to achieve in the lower speed range, the dynamically rising torque curve, and thus the drivability improve. The decreasing torque at higher speeds increases the torque of the motor. In addition, the high maximum speed (7,200 rpm) underlines the sport engine-character of the M-139.

“Already with the previous engine, we have set the Benchmark in the Segment. With the new four-cylinder, we were faced with the challenge to surpass these top riders. We achieved this with revolutionary solutions. With the M-139, we have proved once more the high level of engine expertise of Mercedes-AMG impressively. Not only is the capacity in litres is for a boosted engine is unique, so the high efficiency shows that the combustion engine still has potential,“ said Tobias Moers, Chairman of the Board of management of Mercedes-AMG GmbH.

Content

- Why One Man, One Engine“ what is meant to be

- Why a 180-degree turn brings many benefits

- As the roller Bearing improves the response behavior of the turbocharger

- How the electronic load pressure control response is optimized

- What are the advantages of the crank-casing provides

- Why are the cylinder liners with nano-slide are coated

- As larger exhaust valves provide for a faster gas exchange

- As the fuel injection combines the Best of two worlds

- Like the elaborate cooling system increases the performance

- Why the electric water pump offers many advantages

- As the new production makes work easier and increases efficiency

- How is the new Monday, the work the car easier

- Why employees speak of the “Blue Sky”

- What are the benefits of driverless transport systems

- Why the inspection stations were even more efficient

- The data in The Overview

Why One Man, One Engine“ what is meant to be

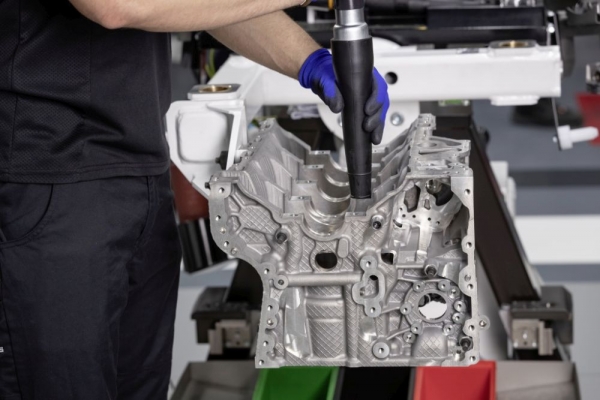

The new engine will be assembled entirely by hand. On the first floor of the AMG Engine factory in Affalterbach, a completely new designed production line at the Mercedes-AMG principle of “One Man, One Engine” together with the industry 4.0 on an innovative level, which is designed according to the most modern knowledge of ergonomics, product flow, quality assurance, sustainability and efficiency was created to be. On the way to the implementation of industry 4.0, the AMG Manufaktur manufacturing pursues the Vision of smart production. This is characterized by maximum flexibility, is transparent and highly efficient. In the process it ensures and enhances the quality of the engines, as well as the production processes with innovative digital technologies.

“For the Assembly of the M-139, we have thought the principle One Man, One Engine in a completely new way. The result is a state-of-the-art manufacturing, the focus on the people. For our employees, we have established the optimum working conditions in a light-filled, precise, organized, and clean environment. This provides the best Basis to ensure our high quality level, so in the case of complex technology,“ said Emmerich Schiller, COO and member of the Board of management of Mercedes-AMG GmbH.

Why a 180-degree turn brings many benefits

The new engine features a range of intelligent construction details. Compared to the transverse M 260 four-cylinder in the 35 models or the previous M 133 of the new Mercedes-AMG M 139 is rotated 180 degrees around the vertical axis. This means that The turbocharger and the exhaust manifold are seen in the driving direction behind the side of the bulkhead to the interior. The intake system is positioned accordingly, the front. This design allows a flat and therefore aerodynamically advantageous front design. So, could be realized by rearranging a significantly improved air guide with shorter distances and less bends on the suction and on the exhaust side.

As the roller Bearing improves the response behavior of the turbocharger

The new Twin-Scroll turbocharger combines with superior response at low speeds with high power increase in the upper speed range. The turbine housing is divided into two parallel flow channels. Together with two separate channels in the exhaust manifold, this allows the exhaust gas flows to the turbine wheel separately.

The goal is to prevent a mutual negative influence of the individual cylinders during the charge exchange and improve gas exchange. The result-pay a higher torque at low speeds and a very spontaneous response.

Moreover, the shaft of the compressor and turbine wheel is mounted on roller bearings for the first time ‑ as is the case with the highest level of performance of the AMG 4.0-litre V8 engine of the AMG GT 4-door coupe. By means of the roller Bearing, the mechanical friction in the turbo is reduced loader to a Minimum. The loader therefore is even more spontaneous and rotates faster – a maximum of up to 169,000/min.

How the electronic load pressure control response is optimized

With a maximum boost pressure of 2.1 bar (1.9 bar in the base model) are ranked the 2.0-Liter four-cylinder turbo engine, so in this point at the top. With the electronically controlled Wastegate (exhaust-pressure relief valve) the charge pressure even more precise and flexible rules, and the response characteristic to optimize, in particular, in the case of acceleration from a part load. A large number of parameters is taken into account.

The main input signal for the control device of the waste gate regulating boost pressure, throttle position, and knock tendency. Among the correction signal, intake air temperature, engine temperature, engine speed and ambient air pressure. So, a temporary Overshoot of the boost pressure during acceleration (Overboost), it is possible to.

For cooling of the turbocharger is used in addition to Oil and water and also fresh air. You will be directed from the radiator grill on the engine cover, which is designed as an air-guiding element, and the channels under the bonnet specifically for the loader. The concept is based on the principles and experiences with the cooling of the inner turbo-charger of the current AMG 4.0-litre V8 engines, with the AMG GT in 2014. In addition, the turbine housing has an integral insulation.

What are the advantages of the crank-casing provides

The all-aluminium crankcase is produced in a gravity die casting method, which is characterized by its excellent material properties. Here, the liquid aluminum is poured under the action of gravity in the permanent metal mold (mould). The water-cooled mold causes due to their thermal conductivity, rapid cooling and solidification of the melt. This has a fine-grained and dense structure, which guarantees very high resistance values. With the help of pickled sand cores with complex internal geometries.

The so-called Closed-Deck design – a design from the Motorsport ensures the highest rigidity at a low weight and top-of-the combustion system enables pressures up to 160 bar. The areas of the cylinders are closed as much as possible, and the deck plate is only broken by smaller channels for the coolant and the engine oil. The crank Assembly with forged, lighter crank steel shaft and forged aluminum pistons with optimized piston ring, which combines low friction with high strength. The maximum engine speed is at 7,200 rpm, the maximum power is reached at 6,750 rpm. The oil Pan features baffle plates, so that in spite of the increased Ölsumpfs even at high lateral acceleration will always be enough oil for the lubrication of all relevant components is available.

Why are the cylinder liners with nano-slide are coated

To reduce the Friction between the piston and the cylinder, the raceways of the patented nano slide technology coated.

This is the careers of the mirror smooth for minimum friction, in addition, twice as hard as conventional cast iron liners and therefore much more durable makes. Nano-slide was developed by the Daimler AG and is protected by more than 90 patent families and over 40 patents. The coating was first used in the AMG engine M 156, refined for many years, other AMG engines, and is also found in the formula 1 engine from Mercedes AMG Petronas Motorsport.

As larger exhaust valves provide for a faster gas exchange

The cylinder head could be to run the injectors through the newly – positioned and to each other slightly angled and location of Spark plugs on the exhaust valves compared to the predecessor engine M 133 significantly larger. The larger outlet cross-sections enable the low-loss Outflow of the exhaust gas from the combustion chamber and reduce the entire piston extending work.

A more efficient cylinder head cooling could be achieved through the installation height reduced seat-ring, and a combustion chamber near the cooling hole in the web area between the exhaust seat ring. The cooling performance enhanced by a near-surface water-jacket geometry, a faster flow speed, and the optimized volume flow.

A multi-layer metal beading seal on the latest state of the art seals the cylinder head and the crankcase to each other.

Two overhead camshafts to control weight-optimised roller-type Cam followers the 16 valves. The camshaft adjustment on the inlet and outlet side enables an excellent throttle response and optimizes the charge cycle for each operating point. Add to this the variable valve control system CAMTRONIC on the outlet side with two Cams per valve. The Cams have different geometries, so that the exhaust valves depending on the Cam circuit, which is dependent on the driving situation, short or long open – for better response at low revs, comfortable and consumption-optimised Driving at medium speeds, and full power delivery in the upper rpm range.

Mercedes-AMG production M139 2019

As the fuel injection combines the Best of two worlds

Turbo-charging and direct injection with spray-guided combustion processes not only provide a high power output, but also increase the thermodynamic efficiency and therefore reduce fuel consumption and exhaust emissions.

For the first time, the new high-performance four-cylinder has a two-stage fuel injection. In the first stage, quick and accurate work of transport, especially at the end of the Piezo-injectors the fuel up to 200 bar pressure in the combustion chambers. This can be done multiple times and is controlled by the motor control.

In the second stage, a suction tube-channel injection with solenoid added valves. This is needed to Achieve the high specific power of the engine. The electronically controlled fuel supply operates with a pressure of 6.7 bar.

Like the elaborate cooling system increases the performance

The high performance requires a sophisticated cooling system. An additional cooler in the wheel arch adds to the large Element in the front plane of the main modules. In addition, a low-temperature circuit for the air-to-water-comes-air cooling load to be used. Together with the series-connected charge air cooler water pump cooler using an electric high-performance flows. The highly compressed charge air is cooled in this way optimally to support the maximum performance of the engine.

The cooling of the transmission oil is integrated in the water circuit of the engine and is supported by a directly on the gearbox attached to the heat exchanger. The engine control unit sits on the air filter housing and is surrounded by a flow of cooling air.

Why the electric water pump offers many advantages

The demand-controlled, electric high-performance water pump operates independently of the engine speed. The late Turn on the Warm-up accelerates the Heating of the engine block, which has a positive effect on Friction, fuel consumption and emissions.

Can also be used to pay for operation with less power or low rpm, the pump needs switched on or off. The electric water pump also ensures full engine power and optimal heat dissipation over the entire speed range. It also protects against heat damage in idle mode at very high outside temperatures.

Functions, such as generator management, ECO Start-stop function, with fast re-start, the sails function, and the Otto of the particle filter are also part of the technology package of the new AMG four-cylinder.

As the new production makes work easier and increases efficiency

The new AMG 2.0-litre four-cylinder turbo engine with the internal designation M 139 is mounted entirely by hand according to the traditional AMG philosophy of “One Man, One Engine” – but with a completely new, digitally-supported process and logistics organization.

In all activities the person is at the centre. The employees are supported through the use of digital Tools in their activities. The use of intelligent, flexible technology is in the focus. The core element of modern production, the combination of a highly flexible Assembly Line with a pre-configured shopping cart, and driverless transport systems. So, the topic of sustainability and what a fundamental part in the planning of the new production line for the M-139. The production uses renewable energy and reduces CO2 emissions, water consumption and waste significantly.

How is the new Monday, the work the car easier

The mounting carriage on which the M-139 is assembled, together with the staff in the Team. He has an own, independent power supply and therefore requires no power cable. All the necessary resources and tools are ergonomically optimized and the car, which facilitates equally the work of the paths is minimized and the efficiency increased. The built-in Tablet PC support the technician with precise work instructions in clear, understandable terms. Hand-books or guides have finally retired, the factory is paperless.

Why employees speak of the “Blue Sky”

The new cordless screwdrivers are immediately to Hand and not have to ‑ as yet ‑ to be used from Station to Station as a wired tool from the hall ceiling. The employees call their workplace, therefore, “Blue Sky”, because no more wires hanging from the ceiling. The overall impression in the light-flooded hall is very bright and airy and a pleasant place to work creates the climate. The comprehensive digitization increases both the efficiency and the flexibility in manufacturing: Each tool is associated with the Wi – Fi of the engine manufactory, the sharing, and the torque setting for the mounting can be done section, therefore, automatically on the Indoor Tracking. In addition, all completed activities are recorded digitally, which guarantees the highest level of quality assurance, traceability and transparency.

What are the benefits of driverless transport systems

Each mount, and is followed by a driverless transport system. In his shopping cart all the components are exactly in stock, which are to complete the respective engine is required. The transport system are picked in the Mercedes-AMG logistics center Marbach and down to the beat (just in sequence) delivered to the production line. The Autonomous control is performed in Indoor Tracking via Wi-Fi. All the components can be digital keep track of.

Assembly and transport of white Mercedes cars are in black – and-AMG Look-designed with headlines such as “START YOUR ENGINE” or “AMG PERFORMANCE INSIDE” labeled. In order to contribute to the Motivation and identification with the company. Fits to the floor of the hall received the hatches, and white-red stripe markings, which are reminiscent of Curbs and guidelines of the tracks.

Why the inspection stations were even more efficient

In Parallel, the number of inspection stations has been reduced by several individual stations were combined to form three Central stations: drag-torque test, leak test Oil, water and fuel systems and leak testing of the complete water space of the engine. This results in considerable time advantages and thus a higher efficiency.

Here too, all parameters and measured values are digitally recorded and stored, so that at any time the emergence of each individual motor can be tracked.

The Monday philosophy of “One Man, One Engine” is one of the brand-defining characteristics of Mercedes-AMG. Another characteristic feature of the M-139, the AMG Engine plate bearing the signature of the engine Builder is, therefore,. Previously, it was for all the installers of the new four-cylinder extensive qualification and training measures.

The data in The Overview

Mercedes-AMG 2.0-litre four-cylinder turbo engine M 139

Displacement

1.991 cm3

Bore x stroke

83,0 x 92,0 mm

Performance

310 kW (421 HP) at 6,750/min (S-model)

285 kW (387 HP) at 6,500 rpm (base model)

Max. Torque

500 Nm at 5.000-5.250/min (S-model)

480 Nm at 4,750-5,000 rpm (base model)

Max. Speed

7.200/min

Compression

9,0:1

Charging

A Twin-Scroll turbocharger with wälzgelagertem the compressor and turbine wheel

Max. Load pressure

2.1 bar (S-model)

1.9 bar (base model)

Mixture preparation

Combined Direct and manifold injection.

1.) Multiple direct injection of the third Generation. Fast and precise Piezo injectors inject the fuel at high pressure into the combustion

2.) In addition, the suction pipe, channel injection with solenoid valves

Cylinder head

Two overhead camshafts, 16 valves, adjustment of the intake and the exhaust camshaft, the valve opening period adjustment CAMTRONIC for the exhaust camshaft

Max. Air mass flow rate

1.200 kg/h (S-model)

1,100 kg/h (base model)

Motor weight (GZ)

160,5 kg

Mercedes-AMG production M139 2019