27.3.2019. Volkswagen and Amazon Web Services together to build the Volkswagen Industrial Cloud. Both companies announced a multi-year development co-operation.

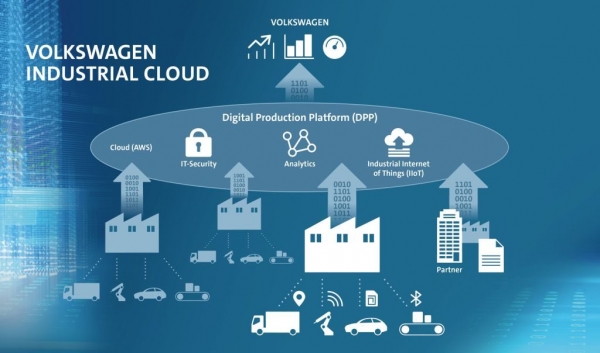

In the Volkswagen Industrial Cloud in the future, the data of all machinery, equipment, and systems from all of the 122 factories of the Volkswagen group are managed together. This helps to optimize workflows and processes in manufacturing, productivity increases in the works.

The Industrial Cloud of Volkswagen, to create important technological prerequisite for the achievement of the productivity targets in the production. In the long term, it is also about the Integration of the global supply chain of the Volkswagen group ran with over 30,000 locations from more than 1,500 suppliers and partner companies. Together with Amazon Web Services Volkswagen sets up its Industrial Cloud, therefore, as an open industry platform, the perspective can also make use of other partners from industry, logistics and trade.

“We will strengthen the production as a competitive factor for the Volkswagen group. Our strategic partnership with Amazon Web Services creates important prerequisites,“ says Oliver Blume, Executive Board Chairman of Porsche, and the Board of management of Volkswagen AG with responsibility for production. “The Volkswagen group wants to add its global Expertise in automotive manufacturing and Amazon Web Services with its technology Know-how. With our global industry platform we want to create a growing industrial Ecosystem, from its transparency and efficiency benefit everyone Involved.“

“The Industrial Cloud of Volkswagen wants to transform the production and logistics of the company. It is a further proof of the innovative strength and technology leadership of Volkswagen“, says Andy Jassy, CEO of Amazon Web Services. “The cooperation between Volkswagen and Amazon Web Services, will improve the efficiency and productivity in the global supply chain of Volkswagen continue to promote.

In the future, Volkswagen wants to take advantage of the Cloud with the broadest and most in – depth functionality, the most innovation, the highest levels of Performance and security, and the largest group of partners and customers in all infrastructure providers. We are in close consultation with Volkswagen, to assist in shaping the future of the automotive production and to benefit from all the advantages of the Cloud.“

Content

- IT at the production level will be uniform and linked

- Optimization of processes, rapid Integration of new technologies

- As an industrial platform for other companies

- Industrial Cloud of Volkswagen is driven to several IT centres in the

IT at the production level will be uniform and linked

With the construction of its Industrial Cloud, the Volkswagen group is creating the basis for an end-to-end digitisation of its production and logistics. IT on the manufacturing level of machinery, plants and systems for production planning and warehousing – about all 122 production sites of the Volkswagen group are uniform and linked. So far, it differs in Parts from location to location.

In their cooperation, both companies rely on the Amazon technologies in the areas of Internet of things (IoT), machine Learning, and Computing Services designed specifically for the production environment and the requirements of the automotive industry, has expanded. As the architecture of the new Digital Production Platform (DPP) of Volkswagen, in the future all sites in the group as well as other companies to dock. This platform unifies and simplifies the system – and plant-wide data exchange.

Optimization of processes, rapid Integration of new technologies

Volkswagen wants to develop its Industrial Cloud-new ways to increase efficiency and flexibility in production. The merging of the data from all of the factories creates new perspectives for the optimization of workflows and processes. A more efficient control of the flow of material, the early detection and correction of bottlenecks, and process disturbances, and optimized operation of machines and equipment in each factory.

In addition, the cloud-based platform with its simplified data exchange is a crucial prerequisite for Volkswagen, new technologies and innovations quickly and across locations. These include intelligent robotics, or functions of the data analysis include, for example, to analyze cross-plant processes and to compare. New applications, for example in the IT security for systems that can be scaled with the cloud-based platform directly to all worldwide locations. Volkswagen is committed to Best Practice-experience of Amazon Web Services.

As an industrial platform for other companies

Volkswagen sets up its Industrial Cloud as an open platform. The goal is to integrate companies from the entire value chain of the automotive industry and to industrial partners in the network of the data base and information of all partners benefit. In the long term, it is also about the Integration of the global supply chain of the Volkswagen group ran with over 30,000 locations from more than 1,500 suppliers and partner companies. It is conceivable, moreover, that the Cloud platform will basically be the same for other automotive manufacturers. As a continuously growing, world-wide industrial Ecosystem.

Negotiations with major industrial companies that have interest in Migration in the Volkswagen Industrial Cloud, are already underway.

Industrial Cloud of Volkswagen is driven to several IT centres in the

Teams of experts from Volkswagen and Amazon Web Services to drive forward the Industrial Cloud together. In the medium term, it should be around 220 specialists in several IT development centres of Volkswagen. In Berlin, the companies are planning a joint Industrial Cloud Innovation Center. Furthermore, the Volkswagen experts in Dresden, Munich and Wolfsburg to support the development work. This starts from now. Already, the Teams have defined 140 projects. A service for the localization of the transport of Goods within and outside the factory, such as by Truck (Vehicle Locating Service), as well as analysis services for the calculation of the effectiveness of the System in the locations (Overall Equipment Effectiveness, OEE). The goal is to take the Volkswagen Industrial Cloud, as well as first concrete Services and functions by the end of 2019 in operation.

Volkswagen and Amazon Web Services to develop Industrial Cloud (photo: Volkswagen AG)