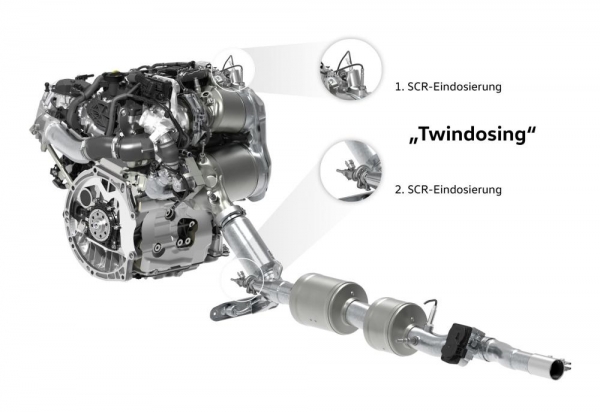

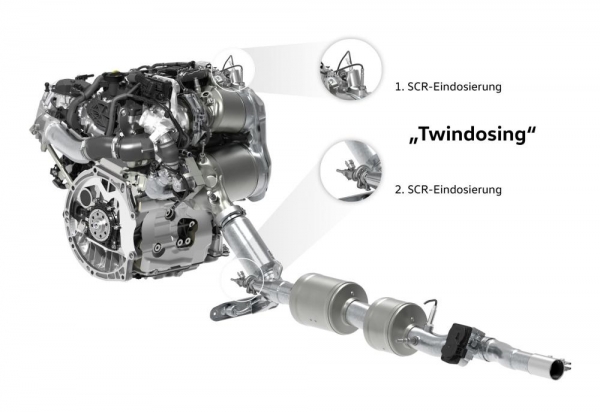

30.8.2019. Since 2018, only the SCR-exhaust gas after-treatment systems in Volkswagen models with diesel engines. With the SCR technology (Selective Catalytic Reduction) of nitrogen oxides is reduced in the exhaust gas significantly. Now, Volkswagen has developed the next step in the evolution of the SCR system, the so-called “twin-dosing”method.

Here, Adblue is injected specifically in front of two successively arranged SCR catalysts is inserted. The procedure comes in the new Passat 2.0 TDI Evo with 110 kW (150 HP) to use. He brings so already now the technical requirements to meet the future exhaust gas norm Euro 6d.

Current RDE measurements (Real Driving Emissions) to the type-Approval of Volkswagen, confirm: With the new 2.0 TDI Evo-engine with twin dosing procedure reduces the NOX values compared to the previous generation of the respective models by about 80 percent.

Volkswagen will introduce the new technology step-by-step now for all models with 2.0 TDI Evo-engine. According to the currently in the Passat used 2.0 TDI Evo with 110 kW (150 HP) wants to.continue in a similar Form of the new Golf, which will celebrate its world premiere, in all TDI variants on twin dosing

For the twin dosing method, a second SCR-catalyst is necessary, which is located in the vehicle underbody. Due to the greater distance to the engine, the exhaust gas temperature before the second catalyst up to 100 °C lower. Thus, the window is extended for the exhaust gas after-treatment: in the case of engine near the exhaust gas temperatures of +500 °C can achieve the overall system very high conversion rates. A lock-Kat behind the SCR-System, prevents the slip of excess ammonia.

The innovative twin dosing method is similar to a system-related disadvantage of diesel engines. Although modern cause auto-ignition less CO2 emissions than gasoline, because diesel fuel has a higher energy density and the combustion process reaches a higher degree of efficiency. However, diesel engines also provide special requirements, since the combustion of the fuel takes place with air excess. Our air consists mainly of nitrogen, which react during combustion with the oxygen – nitrogen oxides are produced.

In order to reduce the diesel engine resulting oxides of nitrogen, is ammonia needed. This is metered as an aqueous urea solution (AdBlue), a dosing module to the exhaust gas before the SCR catalyst. There is the solution evaporates, the urea is cleaved and steam combines with water to form ammonia. In the SCR catalyst the ammonia (NH3) reacts to a special coating, with the oxides of nitrogen (NOx) into water and harmless nitrogen (N2), the main component of the air we breathe.

In previous exhaust aftertreatment systems, SCR catalyst close to the engine between the exhaust-gas turbocharger, the diesel oxidation catalyst, the unburned hydrocarbons that converts substances and the flexible connector to the silencer pipe is placed. The SCR coating is applied to the honeycomb structure of the diesel particulate filter, so that a component can assume multiple functions.

Due to the near-engine arrangement can be achieved after a cold start quickly for high conversion rates, the required exhaust gas temperatures – the ideal area with conversion rates of more than 90 percent at temperatures between +220 °C and +350 °C. In many situations these conditions are met.

Above +350 °C the conversion does not decrease in Council, thanks to twin dosing now. Search high temperatures occur, for example, in the case of fast highway driving, at high speeds over a longer period of time, or, in the case of mountain trips, especially with a fully Laden vehicle or when towing a trailer.

People’s cheeks twin dosing (photo: Volkswagen AG)